What is Thermal Imaging?

Thermal imaging (also sometimes referred to as thermography, infrared imaging or thermal scanning) is the means by which humans can see the infrared portion of the light spectrum.

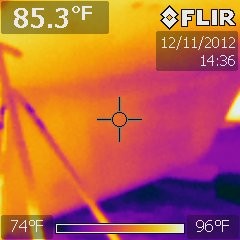

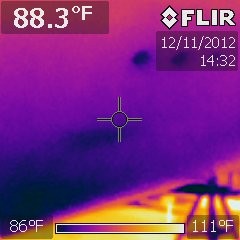

To the left are two images of a Cummins diesel marine engine being operated during a sea trial. The thermal image is on the left and the Thermal MSX® image is on the right.

Left image is of a hull thermal image alone and the right image is the Thermal MSX® image.

As is evident from the images above the MSX® technology in the FLIR® camera provides a crisp clean image which enables us to better detect and locate potential problems.

What Does This Mean to Me and How Does it Help?

The use of thermal imaging in marine surveying enables the trained surveyor the ability to identify potential problems that may not be detectable using traditional surveying tools and equipment. Marine surveys are performed using “non destructive” methods meaning as a general rule we do not disassemble a component for inspection. We observe a bearing for example to detect any misalignment or excessive wear without removing the item and testing the equipment such as an alternator, power steering pump or an electrical panel. If any malfunction or potential problem cannot be seen by the naked eye or heard, a surveyor may not be aware a potential problem exists. The use of a thermal scan can identify potential problems such as bearings, heat exchangers for engine cooling systems or manifolds and/or risers as an example. Thermal scanning may identify a coolant blockage which may cause harm to the engine. This can be done without removing the item from the engine and inspecting it disassembled. An electrical panel powering the onboard electrical system is another area where the use of thermal scanning can identify potential problems that would not be detected without a qualified marine electrical technician checking each and every circuit. We are not suggesting that the need for mechanical or electrical technicians are now not required but it enables the surveyor too possibly identify potential problems prior to the purchase.

How Does Thermal Imaging Work?

Every object gives off some amount of thermal radiation so thermal imaging is ideal for observing temperature anomalies that are abnormal in machinery, electrical equipment, and even solids such as wood, fiberglass, aluminum, and steel. Thermal imaging does not require light to see thermal radiation (like you would see in night vision cameras which require some amount of light) so thermal cameras can see in absolute darkness. Thermal imaging is used widely in other industries for maintenance and pre-failure inspections of machinery. Although somewhat new technology in marine surveying, thermal imaging is used extensively in the surveying of commercial aircraft hulls and systems. At Sun Coast Marine Surveying we want to insure our surveyors have the best technology available for our customers.

The tool used for thermal imaging is the thermographic camera, which is similar in appearance and operation of a portable digital video camera. Our company uses FLIR® brand infrared cameras. We use specific FLIR® camera’s that utilize MSX® Thermal Image Enhancement. Not all FLIR® cameras have this MSX® technology and it is only available on FLIR® brand cameras. MSX® adds key details from the onboard visible light camera to the entire infrared image in real time. The result: an all-in-one thermal picture with numbers, labels, and other structural features intact so you’ll instantly recognize where the potential problem is and more easily recognize the object.

The tool used for thermal imaging is the thermographic camera, which is similar in appearance and operation of a portable digital video camera. Our company uses FLIR® brand infrared cameras. We use specific FLIR® camera’s that utilize MSX® Thermal Image Enhancement. Not all FLIR® cameras have this MSX® technology and it is only available on FLIR® brand cameras. MSX® adds key details from the onboard visible light camera to the entire infrared image in real time. The result: an all-in-one thermal picture with numbers, labels, and other structural features intact so you’ll instantly recognize where the potential problem is and more easily recognize the object.

A special lens on the infrared camera focuses the infrared light emitted by all of the objects in view. With MSX® the camera has an additional lens which captures a digital picture and each image actually produces three images. Using the FLIR® software each image can be viewed in three different formats.

1. Digital Image 2. Thermal Image 3. Thermal MSX

The Thermal MSX image actually overlays the digital image over the thermal image to produce an image that is clear and easier to recognize.

What are the Key Benefits of Thermal Imaging?

Thermal imaging has several advantages across numerous industries. It has several benefits for the marine industry. These benefits include:

- Contact is not required. Thermal imaging keeps the surveyor safe by making it possible to inspect moving, and hot engine-room components while the engine is running. The technique also enables a surveyor to inspect electrical components at high voltage without the risk of being electrocuted.

- It happens instantly. Thermal imaging permits the scanning and recording of stationary targets.

- Thermal patterns are visible. This drastically cuts down on the time and money spent on a technician or mechanic during a marine inspection. This is good news for you, the customer. Thermal imaging reduces the amount of time needed to disassemble and troubleshoot a component or to search through miles of wiring on a boat or yacht to locate the issue. A temperature anomaly can be found instantly using a thermographic image.

- It improves the marine survey report. On all marine surveys, our business offers this service at no additional charge. Before making a purchase, thermal imaging on parts including engines, gearboxes, tanks, electrical systems, electrical devices, hulls, and decks can find out if the vessel has any faulty parts, leaks, or delamination.

Thermography and How It makes Your Vessel Safer

As you can see in the photos above, thermography can make your vessel (or prospective vessel) a safer investment. Thermography can sense the heat that may prevent an electrical fire. Thermal imaging can detect leaking fuel or water from tanks that may prevent an explosion or water damage to the interior of the vessel. Thermal imaging c

Thermography can make your vessel (or potential vessel), as seen in the photographs above, a safer investment. Thermography has the ability to detect heat, which could put out an electrical fire. Thermal imaging can identify gasoline or water leaking from tanks, potentially preventing an explosion or internal vessel water damage. In engines or transmissions, thermal imaging can identify temperature irregularities that could lead to later, much more expensive engine or transmission repairs.

The concerns with delamination shown in the photos to the right were discovered through the use of thermal imaging. In the field of marine surveying, the use of thermal cameras enables a skilled surveyor to spot potential structural problems that could go unnoticed when using more conventional techniques.

The traditional tried-and-true surveying techniques that have been taught for years are still used in the marine surveying sector. Many of these methods are employed by Sun Coast Marine Surveying and Consulting, including the use of percussion soundings and a GRP33 moisture meter. What sets our business apart from the competition is the extra usage of FLIR® thermal cameras with MSX® Imaging technology.

Thermal image of a onboard generator operating under a load.

Thermal image of a Cummins Diesel engine

Infrared thermal image of hull delamination on the lower right side of the image.

Infrared thermal image of a hull bottom with hidden delamination under the fiberglass